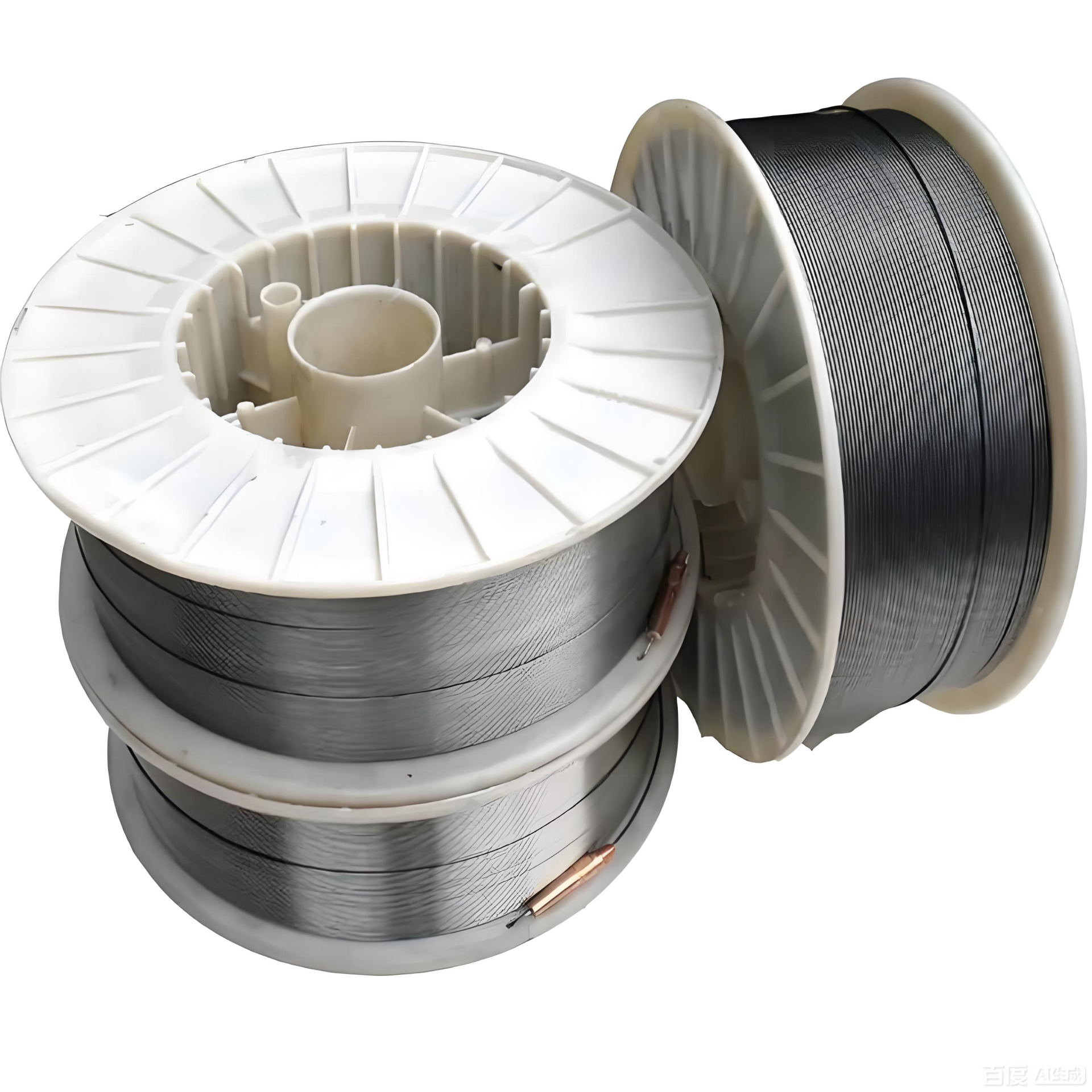

ERNiFeCr-1(ER825) -Nickle Alloy Wire

ERNiFeCr-1(ER825) -Nickle Alloy Wire

Technical Compliance: AWS 5.14 Class ERNiFeCr-1 / ASME SFA 5.14 Class ERNiFeCr-1

Applications

Superior Stress Corrosion Cracking Resistance:

The high nickel content of ERNiCrMo-3 provides exceptional resistance to stress corrosion cracking (SCC), ensuring reliable performance in high-stress environments.Broad-Spectrum Corrosion Resistance:

The alloy exhibits excellent corrosion resistance in a wide range of media, including sulfuric acid, phosphoric acid, nitric acid, organic acids, alkali metals (e.g., sodium hydroxide, potassium hydroxide), and hydrochloric acid solutions. This makes it suitable for demanding chemical processing applications.High-Performance in Nuclear Fuel Dissolution Systems:

In nuclear fuel dissolvers handling mixed corrosive media (e.g., sulfuric acid, nitric acid, and sodium hydroxide), ERNiCrMo-3 demonstrates superior comprehensive performance. Its ability to withstand simultaneous exposure to diverse aggressive environments ensures durability and operational integrity in critical nuclear processing equipment.

Key Benefits:

Enhanced SCC resistance for long-term structural integrity.

Versatile compatibility with acidic, alkaline, and organic media.

Proven reliability in nuclear and high-corrosion industrial applications.

Ideal for: Chemical processing, nuclear fuel cycle systems, and other environments requiring advanced corrosion protection.

| Chemical Composition | ||||||

| ElEMENT | C | Mn | Fe | P | S | Si |

| AWS A5.14% | <0.05 | <1.0 | 22min | <0.03 | <0.03 | <0.5 |

| ADTO WIRE% | 0.01 | 0.5 | 24 | / | / | 0.3 |

| ElEMENT | Cu | Ni | Co | AI | Ti | Cr |

| AWS A5.14% | 1.5-3.0 | 38-46 | / | <0.2 | 0.6-1.2 | 19.5-23.5 |

| ADTO WIRE% | 2.3 | Bal | / | / | / | 22 |

| ElEMENT | Nb+Ta | Other | Mo | |||

| AWS A5.14% | / | / | 2.5-3.5 | |||

| ADTO WIRE% | / | / | 2.8 | |||

| Mechanical Properties | |

| TENSILE TRENGTH | 560MPA |

| Welding Wire Diameter Chart | ||

| WEIGHT | TYPE | OD/MM |

| 15/Coil | Mig | 0.9 |

| 15/Coil | Mig | 1.2 |

| 15/Coil | Mig | 1.6 |

| 5kg | Tig | 1.6 |

| 5kg | Tig | 2.4 |

| 5kg | Tig | 3.2 |

| Stanard Packaging | |

| TIG | 10 Ib.tube/ 60Ib. carton |

| MIG | 30 Ib.spool |

| SUB-ARC | 60 Ib.coil |

| Production Equipments | ||

| EQUIPMENT | QUANTITY | MODEL NUMBER |

| Vacuum melting furnace | 1 | 2 Tons |

| Electroslag remelting furnace | 12 | 50 kg |

| Electroslag remelting furnace | 1 | 2 Tons |

| Wire Rod Annealing furnace | 7 | - |

Wire Drawing Machine | 4 | - |

| Annealing Furnace | 1 | - |

Wire Cutting and Straightening Machine | 1 | - |