ERNiCrMo-3 (ER625)-Nickle Alloy Wire

ERNiCrMo-3 (ER625)-Nickle Alloy Wire

Classification: AWS 5.14 Class ERNiCrMo-3 / ASME SFA5.14 Class ERNiCrMo-3

Applications (Power Plants , Refinery, OFFSHORE & FPSO, Aerospace)

Base Material Welding:

ADTO ERNiCrMo-3 is specifically designed for joining nickel-based alloys such as UNS N06625 (Inconel 625) and UNS N08825 (Incoloy 825). It is also compatible with ASTM-grade materials including B443, B444, B446, B564, B704, B705, B751, B163, B423, B424, and B425.Dissimilar Metal Welding:

The alloy demonstrates exceptional versatility in welding dissimilar combinations of nickel-chromium-molybdenum alloys, stainless steels, low-alloy steels, and carbon steels.Corrosion-Resistant Coatings:

With a low iron content (≤0.25%) and high chromium content (>8.7%), ERNiCrMo-3 is an ideal choice for corrosion-resistant cladding of pipes and tubes. It excels in applications requiring controlled dilution and high chromium deposition, such as in tubing and tubesheet protection.Superior Corrosion Resistance:

The alloy provides outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion, ensuring long-term durability in aggressive environments.

Key Features:

Optimized for high-performance welding of nickel-based alloys.

Enhanced chromium content for superior corrosion protection.

Proven reliability in critical industrial applications.

Ideal for: Oil & gas, chemical processing, marine engineering, and power generation sectors requiring high-integrity welded joints.

Technical Compliance: Meets AWS A5.14 and ASME SFA5.14 standards for ERNiCrMo-3 classification.

| Chemical Composition | ||||||

| ElEMENT | C | Mn | Si | Fe | Mo | Cr |

| AWS A5.14% | <0.1 | <0.5 | <0.5 | <5 | 8.0-10.0 | 20-23 |

| ADTO WIRE% | 0.015 | 0.015 | 0.05 | 0.25 | 9 | 22 |

| ElEMENT | Ni | Nb+Ta | Ti | AI | S | P |

| AWS A5.14% | Bal | 3.15-4.15 | <0.4 | <0.4 | <0.015 | <0.02 |

| ADTO WIRE% | 63.5 | 3.75 | - | - | - | - |

| Mechanical Properties | |

| TENSILE TRENGTH | 790MPA |

| Impact Test | |||

| TEMP. | +20℃ | -40℃ | -196℃ |

| KV | 200J | 170J | 140J |

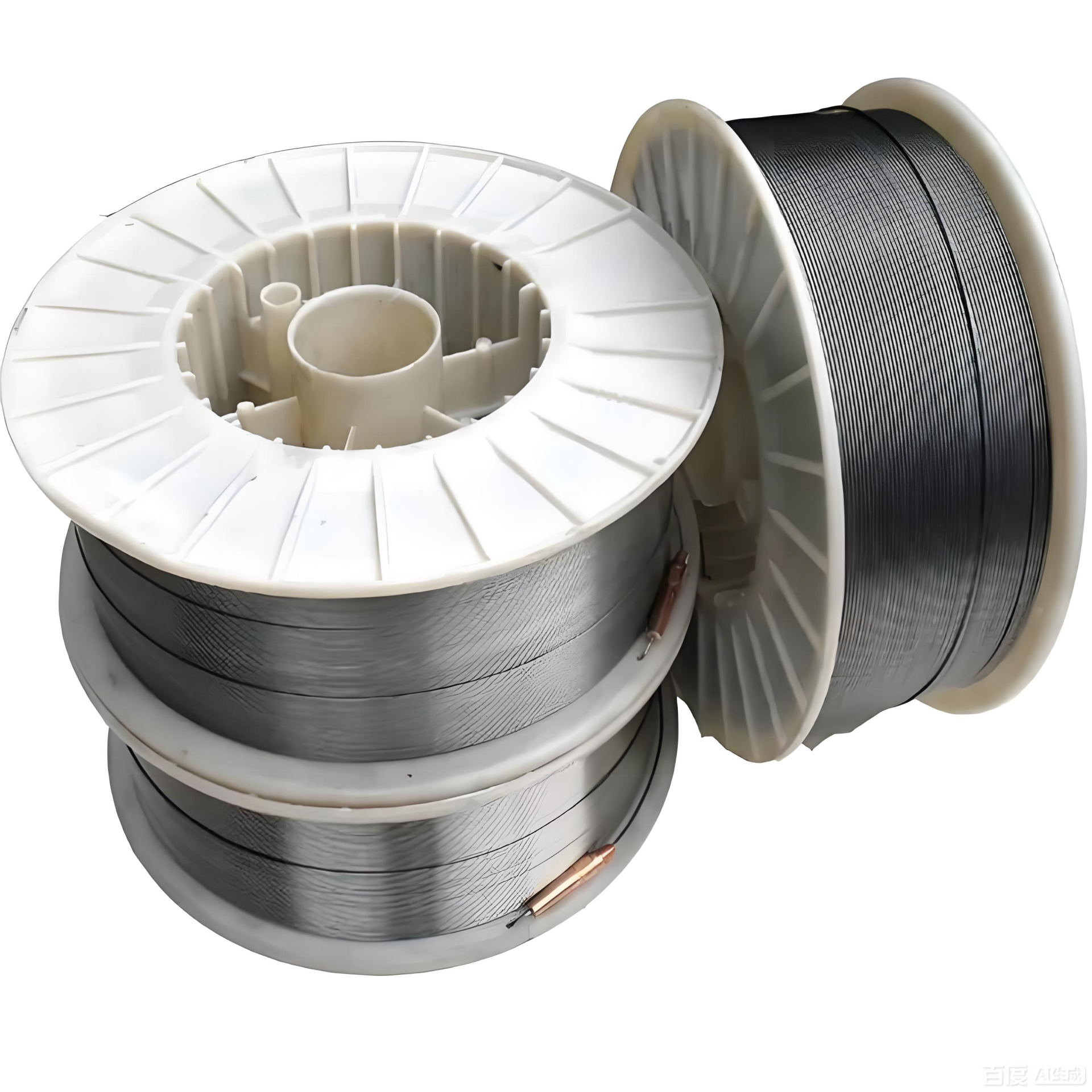

| Welding Wire Diameter Chart | ||

| WEIGHT | TYPE | OD/MM |

| 15/Coil | Mig | 0.9 |

| 15/Coil | Mig | 1.2 |

| 15/Coil | Mig | 1.6 |

| 5kg | Tig | 1.6 |

| 5kg | Tig | 2.4 |

| 5kg | Tig | 3.2 |

| Stanard Packaging | |

| TIG | 10 Ib.tube/ 60Ib. carton |

| MIG | 30 Ib.spool |

| SUB-ARC | 60 Ib.coil |

| Production Equipments | ||

| EQUIPMENT | QUANTITY | MODEL NUMBER |

| Vacuum melting furnace | 1 | 2 Tons |

| Electroslag remelting furnace | 12 | 50 kg |

| Electroslag remelting furnace | 1 | 2 Tons |

| Wire Rod Annealing furnace | 7 | - |

Wire Drawing Machine | 4 | - |

| Annealing Furnace | 1 | - |

Wire Cutting and Straightening Machine | 1 | - |