Unlocking Strength: The Precision Manufacturing Process of Nickel Alloy Forgings

- Views:0

- Author:

- Publish Time:2026-02-04

- Origin:

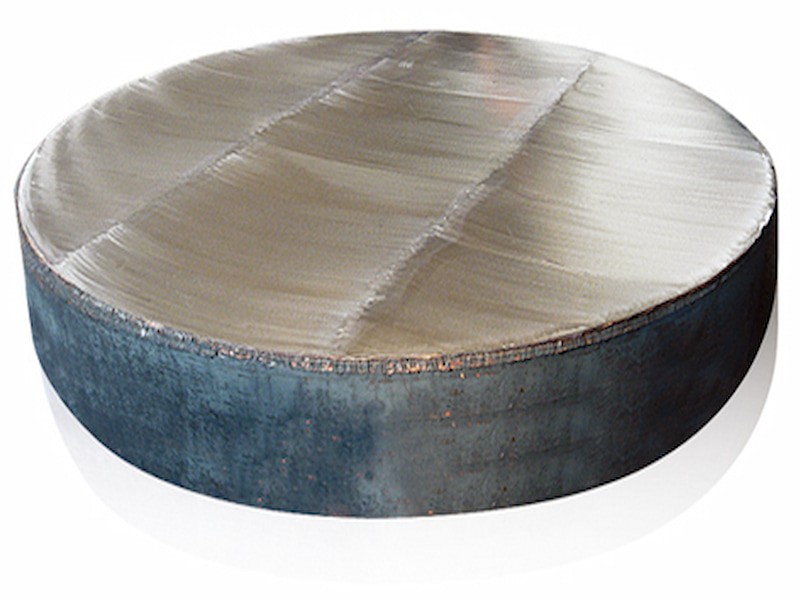

In industries where extreme conditions are the norm—think aerospace engines, deep-sea oil rigs, or high-temperature chemical processing—the choice of material isn't just important; it's critical. This is where Nickel Alloy Forgings prove their indispensable value. But what makes them so reliable? The answer lies in their meticulous manufacturing process.

Unlike standard cast or machined parts, forging transforms nickel alloy under controlled pressure, aligning its grain structure to follow the part’s shape. This creates a continuous flow of metal, significantly enhancing its strength, toughness, and resistance to fatigue and impact. The process typically follows these key stages:

Material Selection & Heating: We start with premium-grade nickel alloys (like Inconel, Monel, or Hastelloy), known for their excellent corrosion and heat resistance. The billet is precisely heated to a high temperature where it becomes pliable but not molten.

Precision Forging: Using immense force from hammers or presses, the heated metal is shaped into a near-net form. This could be done through open-die or closed-die methods, depending on the part's final complexity and requirements.

Controlled Cooling (Heat Treatment): After forging, the part undergoes carefully controlled cooling and subsequent heat treatment. This crucial step relieves internal stresses, refines the microstructure, and unlocks the alloy’s optimal mechanical properties.

Finishing & Quality Assurance: The forged component is then machined to exact specifications. Every piece undergoes rigorous non-destructive testing (like ultrasonic or dye penetrant inspection) to ensure it is free from flaws and meets the strictest dimensional and performance standards.

The result? Components that offer superior integrity, longer service life, and unmatched performance under stress compared to those made by alternative methods.

Why Choose Our Nickel Alloy Forgings?

At HCADTO, we combine advanced forging technology with deep metallurgical expertise. We don't just shape metal; we engineer reliability. Our process is designed to deliver forgings that meet the precise demands of your most challenging applications, ensuring safety, durability, and cost-effectiveness.

Seeking robust solutions for your next project?

Explore our capabilities and let’s discuss how our precision nickel alloy forgings can strengthen your applications.

Visit us: www.hcadto.com

Email: info@hcadto.com