Navigating Choices: Selecting the Ideal Nickel Alloy Material

- Views:0

- Author:

- Publish Time:2026-01-08

- Origin:

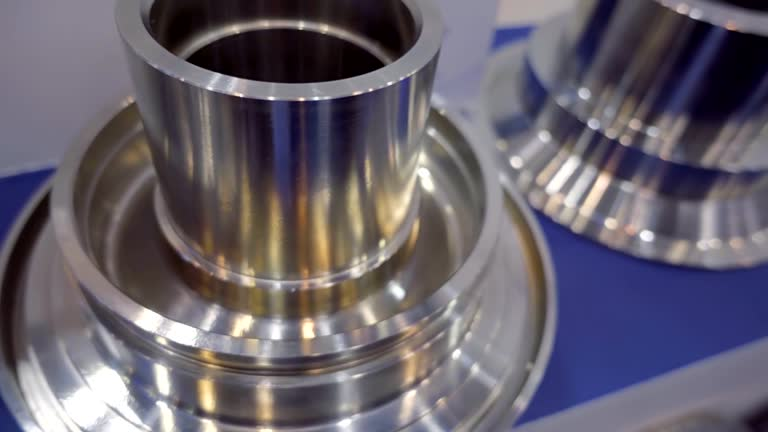

When it comes to engineering and manufacturing, the selection of materials can significantly influence the performance and longevity of a product. Nickel alloys stand out due to their unique properties, but with a variety of options available, how do you determine which is best suited for your application? Let’s explore the key factors in choosing the right nickel alloy material tailored to your needs.

1. Understand the Operating Environment

The first step in selecting a nickel alloy is to assess the working conditions of your application. Consider factors such as temperature, pressure, and exposure to corrosive environments. For instance, if your project involves high-temperature applications, alloys like Inconel® can provide exceptional strength and oxidation resistance, ensuring reliable performance under thermal stress.

2. Evaluate Mechanical Properties

Different nickel alloys possess distinct mechanical properties, including tensile strength, ductility, and hardness. Reviewing these specifications is crucial. If your application requires components that endure significant mechanical stress, alloys with higher tensile strength may be necessary. Conversely, if flexibility is required, look for alloys with better ductility.

3. Corrosion Resistance Requirements

Nickel alloys are celebrated for their resistance to corrosion, but not all alloys offer the same level of protection against specific chemicals or environments. Identify the materials your components will encounter and select an alloy that promises durability. For example, if you're dealing with harsh acidic conditions, alloys like Hastelloy may be the ideal choice due to their excellent resistance to corrosion.

4. Consider Fabrication and Machinability

The ease of fabrication and machining can influence your choice of nickel alloy. Some alloys are easier to work with than others, which can affect production timelines and costs. If your project requires intricate shapes or rapid prototyping, prioritize alloys known for their excellent machinability. This will facilitate a smoother manufacturing process and ensure that design specifications are met accurately.

5. Cost vs. Performance Trade-Offs

Finally, weigh the cost against the performance benefits of different nickel alloys. While high-performance alloys can provide significant advantages, it’s essential to balance budget constraints with the specific requirements of your project. Sometimes, selecting a slightly less expensive alloy that still meets your needs can lead to considerable savings while maintaining product integrity.

Conclusion

Choosing the right nickel alloy material is a vital step toward ensuring the success of your engineering project. By understanding the operating environment, evaluating mechanical properties, and considering fabrication ease and cost, you can make an informed decision that aligns with your application’s needs.

To explore our wide range of nickel alloy products and find the perfect material for your project, visit [www.hcadto.com] or contact us at info@hcadto.com. We are here to help you make the right choice for your success!