Beyond the Grade: Why Processing Quality is Key for Stainless Steel Sheets

- Views:0

- Author:

- Publish Time:2025-09-19

- Origin:

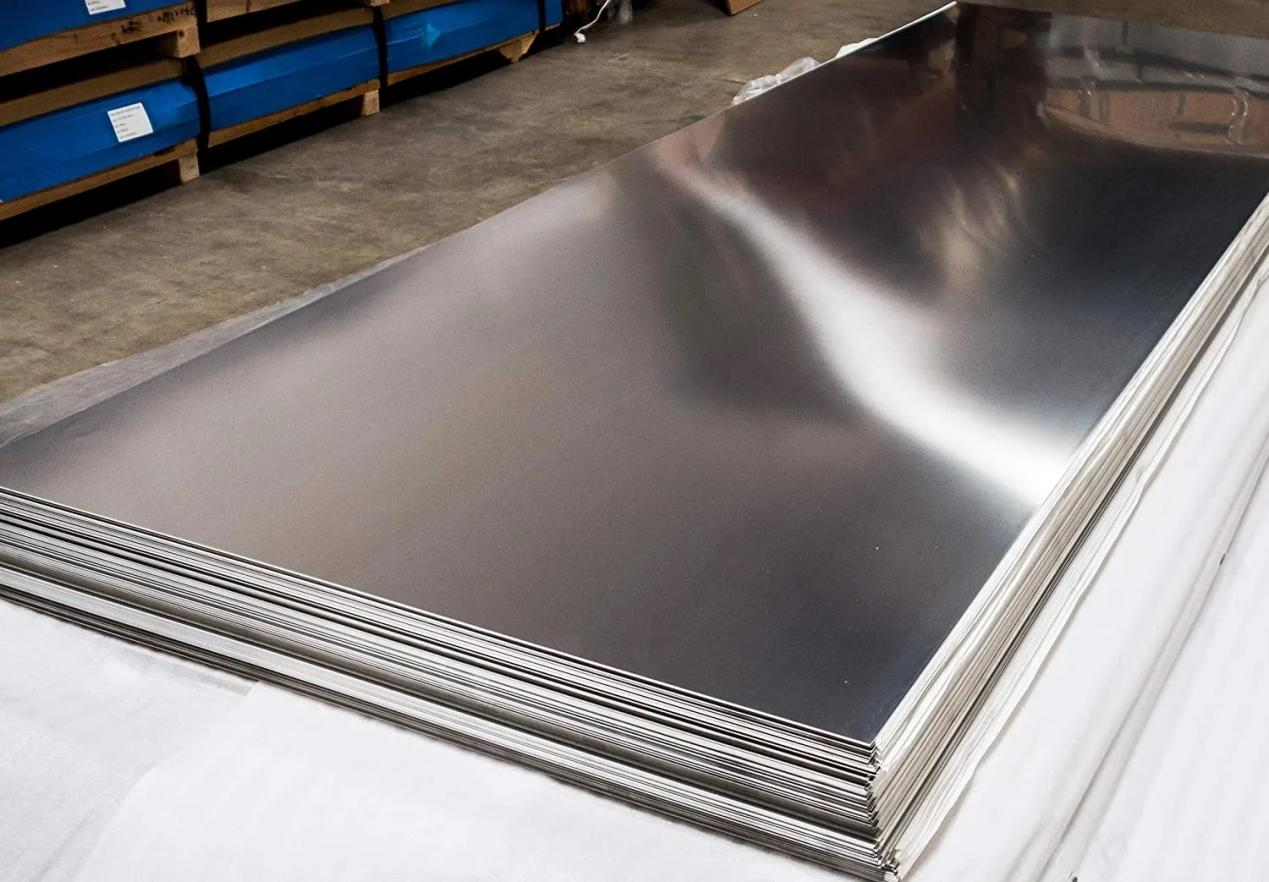

When it comes to sourcing stainless steel sheets, many buyers focus solely on the grade, assuming it guarantees quality and performance. However, this approach can be misleading. While the grade is important, the processing quality of the stainless steel sheets is equally, if not more, critical to their overall performance. Let’s explore why understanding processing methods matters and how it can impact your purchase decisions.

The Significance of Stainless Steel Grades

1. Understanding Grades

Stainless steel comes in various grades, each designed for specific applications. For example:

Grade 304: Known for its versatility and corrosion resistance, commonly used in food processing and kitchen equipment.

Grade 316: Offers superior corrosion resistance, particularly in marine environments, making it ideal for shipbuilding and chemical processing.

2. The Grade Fallacy

While selecting the right grade is essential, it’s important to remember that the grade alone does not determine the material’s overall quality.

Potential Pitfalls: Relying solely on grade can lead to overlooking critical factors such as manufacturing techniques, surface finish, and mechanical properties.

The Importance of Processing Quality

1. Manufacturing Techniques

The method used to produce stainless steel sheets significantly influences their performance characteristics.

Cold Rolling vs. Hot Rolling: Cold-rolled sheets are typically stronger and have a smoother finish compared to hot-rolled sheets, which may have a rougher texture. Understanding these differences helps in selecting the right sheet for your application.

2. Surface Finish and Treatment

The surface finish of stainless steel sheets affects both aesthetics and functionality.

Finishes Matter: A polished surface can improve corrosion resistance and is often easier to clean, making it suitable for environments like kitchens and laboratories.

Passivation: This chemical treatment enhances corrosion resistance, especially important for applications exposed to harsh environments.

3. Quality Control Standards

Ensuring that the manufacturer adheres to strict quality control standards is vital.

Certifications and Testing: Look for suppliers who provide certifications and conduct rigorous testing on their products to ensure they meet industry standards. This can include tensile strength tests, corrosion resistance evaluations, and dimensional checks.

Making Informed Purchasing Decisions

1. Research Suppliers

Evaluate Reputation: Choose suppliers known for their commitment to quality and processing excellence. Read reviews and seek recommendations to find reputable sources.

2. Request Samples

Testing Before Investing: Whenever possible, request samples to assess the processing quality firsthand. This can help you make more informed decisions before placing larger orders.

3. Focus on Long-Term Value

Consider Total Cost of Ownership: Investing in high-quality stainless steel sheets may have a higher upfront cost but can lead to significant savings in maintenance and replacement costs over time.

Look Beyond the Grade for Quality Assurance

While the grade of stainless steel sheets is an important factor, it’s essential to consider processing quality to ensure you receive the best product for your needs.

Ready to make an informed investment in stainless steel? Contact us to learn more about our high-quality sheets and how our processing techniques set us apart from the competition!